Hydrogen Liquefaction

Get to know the how and why behind hydrogen liquefaction and how our experts create a storage and transportation solution creating endless applications where hydrogen in its true form would be impractical to use as an energy source.

THE SCIENCE BEHIND HYDROGEN LIQUEFACTION

HOW HYDROGEN LIQUEFACTION WORKS

Hydrogen liquefaction is the process of cooling and condensing hydrogen gas to convert it into a liquid state. This is done by subjecting the hydrogen gas to extremely low temperatures, typically below -253°C (-423.67°F), which is its boiling point at standard pressure.

THE PROCESS TO CREATE HYDROGEN LIQUEFACTION

The liquefaction process involves compressing the hydrogen gas to increase its density, and then cooling it down to condense it into a liquid form. The cooling is usually achieved by a combination of cooling methods, such as by using a cryocooler or a heat exchanger to remove heat from the gas, and then using an expansion valve to lower its temperature further.

THE BENEFITS BEHIND HYDROGEN LIQUEFACTION

Liquefied hydrogen has a higher energy density than hydrogen gas, making it more practical to store and transport in certain applications. It is also used as a coolant in various industrial processes, such as in the production of semiconductors and in the superconductivity research.

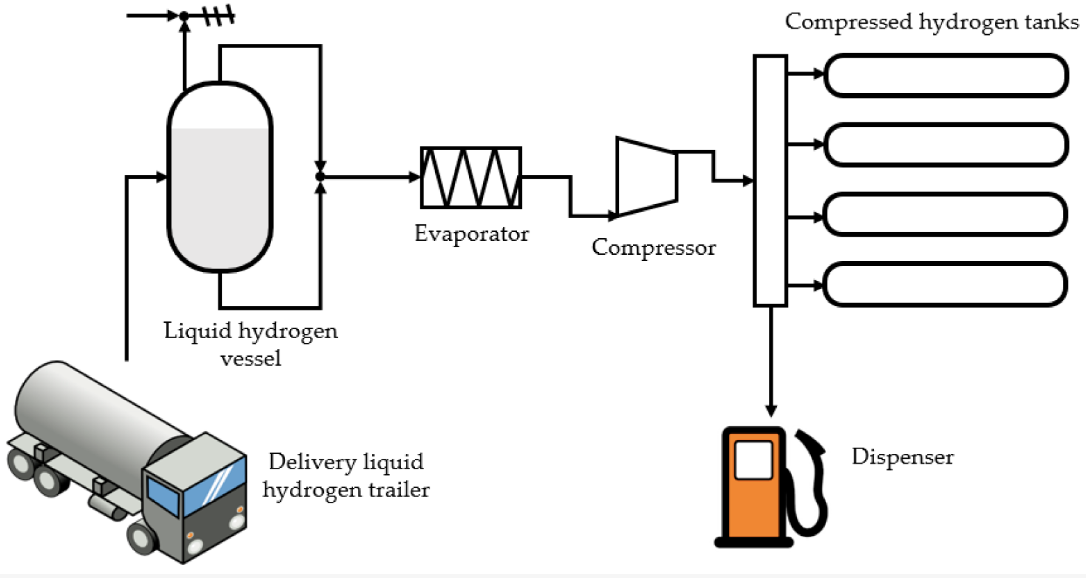

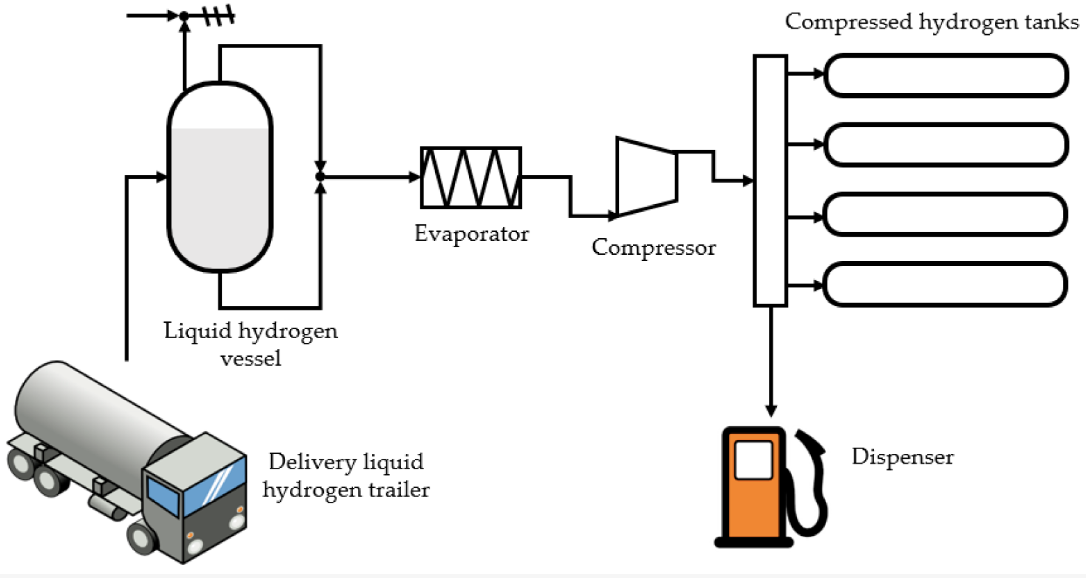

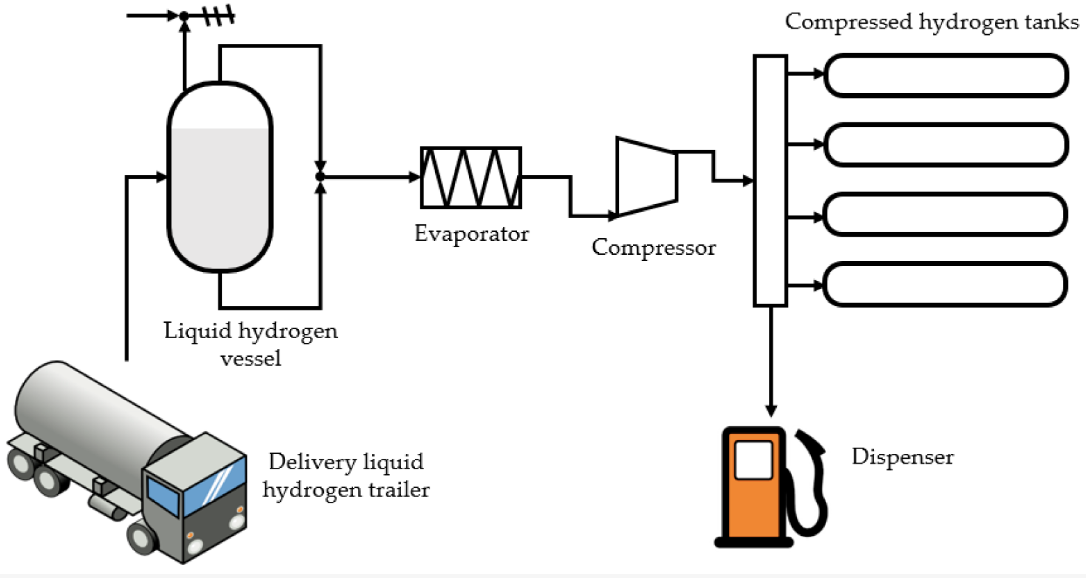

HOW AXIOM HYDROGEN LIQUEFACTION WORKS

9-TO-1 TRUCKLOAD EFFICIENCY

By liquefying hydrogen, our solution enables 9 times more hydrogen to be transported per truckload compared to gaseous hydrogen, making it more efficient and cost-effective.

With our focus on minimizing energy consumption and maximizing efficiency, our customers can enjoy better project feasibility and more progress toward the propagation of global hydrogen fuel applications at scale.

24/7 Green Energy Production

Continuous Night-Time Operation of Ammonia Plants with LH2 Storage Solutions Our LH2 storage solution provides a reliable and cost-effective option for wind and solar farms that are producing ammonia and allows plants to operate continuously day and night. With our integrated air separation unit and hydrogen liquefaction plant, excess LH2 produced during the day can be stored in vacuum jacketed storage tanks for use during nighttime operations. This solution is optimal for plant enabling the efficient use of renewable energy sources and significantly reducing both capital and operating expenses.

Proven Reverse-Brayton cycle

Industry-leading efficiency: Axiom Hydrogen use of a proven Reverse-Brayton thermodynamic refrigeration cycle with dual expanders and demonstrated plate-fin heat exchanger technology results in industry-leading efficiency, with specific energy consumption (SEC) as low as 5.2 kWh per kg liquid-H2.

Ready to discuss your hydrogen hydrogen liquefaction project needs? Submit your information and one of our experts will be in contact with your shortly.

3333 Lake Houston, Unit 16A, Houston, TX, 77098

713-222-2500

###-###-####

Info@AxiomHydrogen.com